embossing wpc outdoor decking board/wpc solid flooring

A.Decking components

The environment friendly WPC outdoor products we produced are made of :

-- 35% HDPE (Grace A Recycles HDPE)

-- 60% Wood fiber (Professionally treated by dry wood fiber)

-- 5% Chemical Additives (Including Anti-UV agent, Anti-oxidation agent , stabilizers, colorants , anti fungus agent , coupling agent , , lubricants ,etc)

| Wood decking | WPC decking |

Maintenance | Requires regular coats of stain or sealant through out its life to remain protected from moisture and sunlight | Never needs to be painted, sanded, stained or sealed, will occasionally require cleaning |

Weathering | Absorb moisture and it is susceptible to mold ,mildew and rot | The plastic adds resistance to moisture and rot, while mold inhabitors can prevent the growth of mold |

Longevity | Because it’s an organic material,it will eventually rot. | Can last 2-3 times longer than wood |

Pests | Vulnerable to insects and termite manager | Highly resistant to insects and termites |

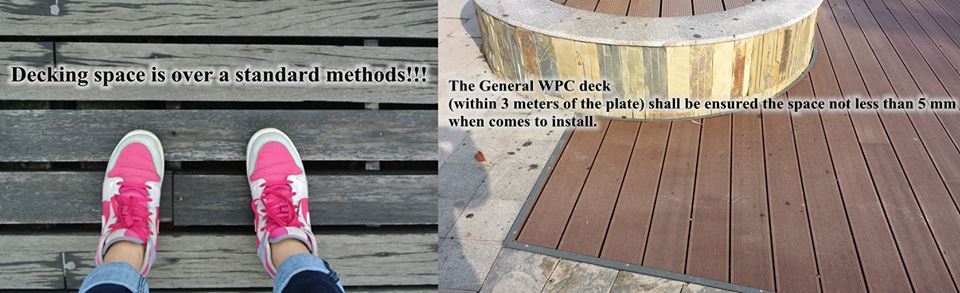

Warping | Has high dimensional stability ,and is more rigid than plastic , but is prone to wrapping and splintering. | Has more dimensional stability than pure plastic ,but may deform under extreme heat .will not wrap, splinter or check |

Environmental Impact | Uses virgin natural resources, which requires the harvesting of lumber | Both the wood and the plastic in a composite deck can come from recycled content varies between manufactures |

Cost | Costs less than composite initially ,but requires regular maintenance costs for the life of the deck | Costs more than wood initially, but makes up for it in saving from maintenance costs |

Step 2:Dig a 1.5cm-deep hole and put the nail in.

Step 3:Combine the two boards and tighten the screw.

Brand | HOH Ecotech |

Established Year | 2007 |

Total Staff | 300~400 |

Research Staff | 7~10 |

International Marketing | 20~25 |

Management System Certification | ISO9001,ISO14001 |

- Tel

- *Title

- *Content